奧創(chuàng)直線振動(dòng)篩中英文使用說(shuō)明書(shū)

振動(dòng)篩' target='_blank'>直線振動(dòng)篩是一種應(yīng)用很廣泛的篩分設(shè)備,與其他振動(dòng)篩相比,具有獨(dú)特的優(yōu)勢(shì)。

Linear sieve is a very extensive application of screening equipment, compared with other vibrating screen, have a unique advantage.

特點(diǎn);characteristics

1)獨(dú)特之篩網(wǎng)結(jié)構(gòu)設(shè)計(jì),方便和快速更換篩網(wǎng) ,此種設(shè)計(jì)允許使用各種篩網(wǎng)。

2)篩機(jī)設(shè)計(jì);精巧和容易裝配,一人即可操作使用。

Sieve machine design; Exquisite and easy to assemble, a person to operation.

3)具有較大篩選面積和高效益處理能力。

With larger screening area and high benefit processing power.

4)較長(zhǎng)的使用壽命,降低耗材使用,生產(chǎn)過(guò)程可降低諸多成本。

Long service life, reduce material use.The production process also can reduce a lot of cost.

直線振動(dòng)篩作用與原理;

Linear sieve functions and principles:

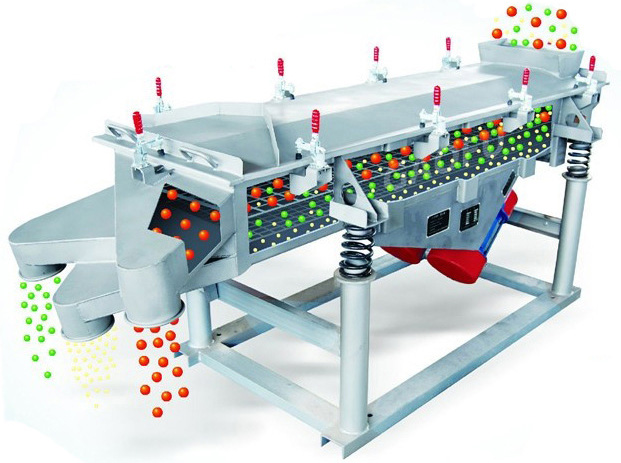

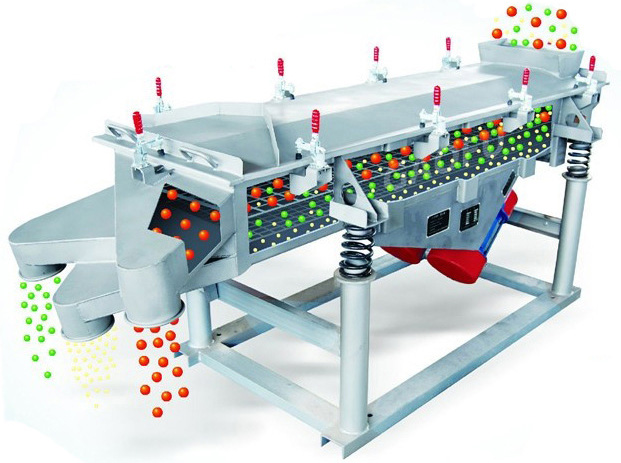

直線振動(dòng)篩是雙振動(dòng)電機(jī)驅(qū)動(dòng)。當(dāng)兩臺(tái)振動(dòng)電機(jī)做同步、反向運(yùn)轉(zhuǎn)時(shí),其偏心塊所產(chǎn)生的激振力在平行于電機(jī)軸線的方向相互抵消,在垂直于電機(jī)軸的方向疊為一合力,因此物料在直線振動(dòng)篩機(jī)上的運(yùn)動(dòng)軌跡為直線向前做拋物線運(yùn)動(dòng)。兩電機(jī)軸相對(duì)篩面有一傾角在激振力和物料自重力的合力作用下物料在篩面上被拋起跳躍式向前作直線運(yùn)動(dòng),從而達(dá)到對(duì)物料進(jìn)行篩選和分級(jí)的目的.

Linear sieve is Double vibration motor driver.When two sets of vibration motor do synchronization and reverse running,the vibration produced by its eccentric block will offset each other in The direction of the axis parallel to the motor.

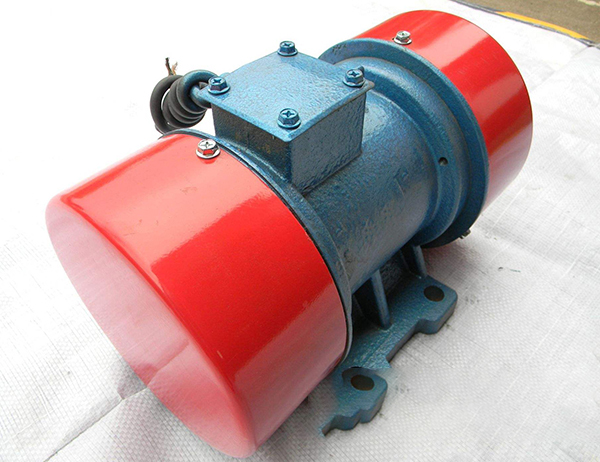

電機(jī)使用說(shuō)明:

Motor instructions:

本系列電機(jī)滿足下列條件時(shí),能連續(xù)輸出額定激振力。

This series motors can continuous output rated of vibration force when they meet the following conditions.

1、振動(dòng)加速度:不超過(guò)7g(g:重力加速度)

1.Vibration acceleration: no more than 7 g (g: gravity acceleration)

2、環(huán)境溫度:不超過(guò)40℃

Environmental temperature: no more than 40 ℃

3、海拔:不超過(guò)1000m

Height: no more than 1000 m

4、電源頻率:50Hz

4.supply frequency :50Hz

5、電壓:380V

5.voltage:380V

6、溫升:小于80K(電阻法)

Temperature rise: less than 80 K (resistance method

直線振動(dòng)篩結(jié)構(gòu)以及各部分功能說(shuō)明

Linear sieve structure and Each part of functional description:

本篩機(jī)主要由篩箱、篩框、篩網(wǎng)、振動(dòng)電機(jī)、電機(jī)臺(tái)座、減振彈簧、支架等組成。

This sieve machine consists mainly of the sieve box, sieve frame, mesh, vibration motor, electrical pedestal, vibration reduction of spring, props etc.

1、篩箱:由數(shù)種厚度不同的鋼板焊制而成,具有一定的強(qiáng)度和剛度,是篩機(jī)的主要組成部分。

1.sieve box are made of different thickness of the steel plates which are welded,has some of the strength and stiffness, the screen is the main part of the sieve machine.

2、篩框:由不銹鋼方管制成,主要用來(lái)粘接篩網(wǎng)作用,達(dá)到正常篩分。

2.sieve frames are made of Stainless steel square tubes.Mainly used for bonding sieve net to to reach normal operation.

3、篩網(wǎng):不銹鋼絲等數(shù)種篩網(wǎng)。現(xiàn)在直線振動(dòng)篩使用的是不銹鋼篩網(wǎng)為304材質(zhì)。

3.meshes:Stainless steel wire and several kinds meshes.Now the use of Linear sieve is stainless steel mesh for 304 material.

4、振動(dòng)電機(jī)(使用與維修方法詳見(jiàn)振動(dòng)電機(jī)使用說(shuō)明書(shū))。

4.vibration motor( Use and maintenance methods as shown in the operation instruction of vibration motor).

5、電機(jī)臺(tái)座:安裝振動(dòng)電機(jī),使用前連接螺釘必須擰緊,特別是新篩機(jī)試用前三天、必須反復(fù)緊固,以免松動(dòng)造成事故。

5.electrical pedestal:After vibration motor installation is complete, the connection screw should be tightened before using.Especially new sieve machine in the three-day trial period,Must tighten again and again to avoid loose and cause accidents.

6、減振彈簧:阻止振動(dòng)傳給地面,同時(shí)支持篩箱的全部重量,安裝時(shí),彈簧必須垂直與地面。

6.vibration reduction of spring:Stop vibration to the ground, and support the full weight of sieve box,the spring should be perpendicular to the floor in installation.

7、支架:由四個(gè)支柱和兩個(gè)槽鋼組成,支持著篩箱,安裝時(shí)支柱必須垂直與地面,兩支柱下面的槽鋼應(yīng)相互平行。

Props: There are four pillars and two channel steel composition, support the sieve box, when installation must be vertical and ground pillar, two pillars shall be parallel the channel.

Linear sieve is a very extensive application of screening equipment, compared with other vibrating screen, have a unique advantage.

特點(diǎn);characteristics

1)獨(dú)特之篩網(wǎng)結(jié)構(gòu)設(shè)計(jì),方便和快速更換篩網(wǎng) ,此種設(shè)計(jì)允許使用各種篩網(wǎng)。

2)篩機(jī)設(shè)計(jì);精巧和容易裝配,一人即可操作使用。

Sieve machine design; Exquisite and easy to assemble, a person to operation.

3)具有較大篩選面積和高效益處理能力。

With larger screening area and high benefit processing power.

4)較長(zhǎng)的使用壽命,降低耗材使用,生產(chǎn)過(guò)程可降低諸多成本。

Long service life, reduce material use.The production process also can reduce a lot of cost.

直線振動(dòng)篩作用與原理;

Linear sieve functions and principles:

直線振動(dòng)篩是雙振動(dòng)電機(jī)驅(qū)動(dòng)。當(dāng)兩臺(tái)振動(dòng)電機(jī)做同步、反向運(yùn)轉(zhuǎn)時(shí),其偏心塊所產(chǎn)生的激振力在平行于電機(jī)軸線的方向相互抵消,在垂直于電機(jī)軸的方向疊為一合力,因此物料在直線振動(dòng)篩機(jī)上的運(yùn)動(dòng)軌跡為直線向前做拋物線運(yùn)動(dòng)。兩電機(jī)軸相對(duì)篩面有一傾角在激振力和物料自重力的合力作用下物料在篩面上被拋起跳躍式向前作直線運(yùn)動(dòng),從而達(dá)到對(duì)物料進(jìn)行篩選和分級(jí)的目的.

Linear sieve is Double vibration motor driver.When two sets of vibration motor do synchronization and reverse running,the vibration produced by its eccentric block will offset each other in The direction of the axis parallel to the motor.

電機(jī)使用說(shuō)明:

Motor instructions:

本系列電機(jī)滿足下列條件時(shí),能連續(xù)輸出額定激振力。

This series motors can continuous output rated of vibration force when they meet the following conditions.

1、振動(dòng)加速度:不超過(guò)7g(g:重力加速度)

1.Vibration acceleration: no more than 7 g (g: gravity acceleration)

2、環(huán)境溫度:不超過(guò)40℃

Environmental temperature: no more than 40 ℃

3、海拔:不超過(guò)1000m

Height: no more than 1000 m

4、電源頻率:50Hz

4.supply frequency :50Hz

5、電壓:380V

5.voltage:380V

6、溫升:小于80K(電阻法)

Temperature rise: less than 80 K (resistance method

直線振動(dòng)篩結(jié)構(gòu)以及各部分功能說(shuō)明

Linear sieve structure and Each part of functional description:

本篩機(jī)主要由篩箱、篩框、篩網(wǎng)、振動(dòng)電機(jī)、電機(jī)臺(tái)座、減振彈簧、支架等組成。

This sieve machine consists mainly of the sieve box, sieve frame, mesh, vibration motor, electrical pedestal, vibration reduction of spring, props etc.

1、篩箱:由數(shù)種厚度不同的鋼板焊制而成,具有一定的強(qiáng)度和剛度,是篩機(jī)的主要組成部分。

1.sieve box are made of different thickness of the steel plates which are welded,has some of the strength and stiffness, the screen is the main part of the sieve machine.

2、篩框:由不銹鋼方管制成,主要用來(lái)粘接篩網(wǎng)作用,達(dá)到正常篩分。

2.sieve frames are made of Stainless steel square tubes.Mainly used for bonding sieve net to to reach normal operation.

3、篩網(wǎng):不銹鋼絲等數(shù)種篩網(wǎng)。現(xiàn)在直線振動(dòng)篩使用的是不銹鋼篩網(wǎng)為304材質(zhì)。

3.meshes:Stainless steel wire and several kinds meshes.Now the use of Linear sieve is stainless steel mesh for 304 material.

4、振動(dòng)電機(jī)(使用與維修方法詳見(jiàn)振動(dòng)電機(jī)使用說(shuō)明書(shū))。

4.vibration motor( Use and maintenance methods as shown in the operation instruction of vibration motor).

5、電機(jī)臺(tái)座:安裝振動(dòng)電機(jī),使用前連接螺釘必須擰緊,特別是新篩機(jī)試用前三天、必須反復(fù)緊固,以免松動(dòng)造成事故。

5.electrical pedestal:After vibration motor installation is complete, the connection screw should be tightened before using.Especially new sieve machine in the three-day trial period,Must tighten again and again to avoid loose and cause accidents.

6、減振彈簧:阻止振動(dòng)傳給地面,同時(shí)支持篩箱的全部重量,安裝時(shí),彈簧必須垂直與地面。

6.vibration reduction of spring:Stop vibration to the ground, and support the full weight of sieve box,the spring should be perpendicular to the floor in installation.

7、支架:由四個(gè)支柱和兩個(gè)槽鋼組成,支持著篩箱,安裝時(shí)支柱必須垂直與地面,兩支柱下面的槽鋼應(yīng)相互平行。

Props: There are four pillars and two channel steel composition, support the sieve box, when installation must be vertical and ground pillar, two pillars shall be parallel the channel.

相關(guān)文章:

- 用會(huì)中術(shù)問(wèn)在技題呢程?斗式提升機(jī)么使都什現(xiàn)過(guò)出

- 奧創(chuàng)往復(fù)式給料機(jī)廠家現(xiàn)場(chǎng)試機(jī)視頻

- 圓形振動(dòng)篩一般使用環(huán)境需要使用不銹鋼材質(zhì)

- 重型振動(dòng)篩屬于篩分機(jī)還是篩分設(shè)備

- 合金粉精細(xì)篩分機(jī)選擇圓盤(pán)篩分機(jī)效果好

- 錫粉振動(dòng)篩廠家解說(shuō)其選型知識(shí)

- 河南醫(yī)藥方形搖擺篩廠家基本集中在河南新鄉(xiāng)

- 河南去石機(jī)廠家解說(shuō)影響工作效率的因素

- 載便攜式吸糧機(jī)廠家解說(shuō)其相應(yīng)知識(shí)

- 圓振動(dòng)篩的型號(hào)和種類(lèi)廠家選哪一種比較好

- YA2160四層圓振動(dòng)篩試機(jī)工作視頻

- 中砂篩沙機(jī)是指中等級(jí)別的篩沙機(jī)使用弛張篩效果好

相關(guān)產(chǎn)品推薦

相信你還想找這些!

篩分篩選機(jī)械

- 石墨粉振動(dòng)篩

- 灰乳轉(zhuǎn)篩

- 振網(wǎng)篩

- 水力篩

- 泥石分離機(jī)

- 平面往復(fù)篩

- 活性炭振動(dòng)篩

- 砂石篩

- 盤(pán)選篩

- 除土篩

- 制砂滾動(dòng)篩

- 金剛砂振動(dòng)篩

- 鑄造篩砂機(jī)

- 陶粒砂成品篩

- 泥漿分砂機(jī)

- 分砂機(jī)

- 圓型振動(dòng)篩

- 分級(jí)振動(dòng)篩

- 醫(yī)藥振動(dòng)篩

- 粉體篩分選篩

- 雙質(zhì)體高頻微粉振動(dòng)篩

- 顆粒分離振動(dòng)篩

- 自動(dòng)清理振動(dòng)篩

- 磁懸浮振動(dòng)篩

- 篩砂機(jī)

- 篩草機(jī)

- 篩料機(jī)

- 激振器式脫水篩

- 大型滾筒篩

- 糖,鹽業(yè)專(zhuān)用搖擺篩

- 圓盤(pán)搖擺篩

- 搖擺振動(dòng)篩

- 超聲波直線篩

- 超聲波搖擺篩

- 垃圾滾筒篩

- 電動(dòng)振篩機(jī)

- 方形振動(dòng)篩

- 篩土機(jī)

- 圓形振動(dòng)篩

- 重型振動(dòng)篩

- 細(xì)粉篩

- 微粉篩

- 復(fù)振篩

- 選礦機(jī)

- 滾動(dòng)篩

- 淀粉振動(dòng)篩

- 顆粒振動(dòng)篩

- 紅棗分級(jí)機(jī)

- 電動(dòng)驗(yàn)粉篩

- 食品用振動(dòng)篩

- 石英砂振動(dòng)篩

- 輥篩

- 砂石骨料振動(dòng)篩

- 粉末振動(dòng)篩

- 分級(jí)篩

- 洗煤振動(dòng)篩

- 液體振動(dòng)篩

- 振蕩篩

- 石子振動(dòng)篩

- 涂料振動(dòng)篩

- 釉料過(guò)濾篩

- 尿素分級(jí)篩

- 珍珠巖專(zhuān)用篩

- 碳素專(zhuān)用篩

- 振動(dòng)砂石分離機(jī)

輸送機(jī)械

- 管式螺旋輸送機(jī)

- 移動(dòng)式螺旋輸送機(jī)

- 垂直螺旋輸送機(jī)

- 蛟龍輸送機(jī)

- 粉煤灰輸送機(jī)

- 冷卻輸送機(jī)

- 板式鏈條輸送機(jī)

- 耐高溫輸送機(jī)

- 食品級(jí)輸送機(jī)

- 折疊皮帶機(jī)

- 水冷螺旋輸送機(jī)

- 板式輸送機(jī)

- 拉鏈機(jī)

- 振動(dòng)整列輸送機(jī)

- 礦用輸送機(jī)

- 波紋擋邊輸送機(jī)

- 瀝水鏈板機(jī)

- 電機(jī)振動(dòng)水平輸送機(jī)

- 鍋爐刮板除渣機(jī)

- 無(wú)軸螺旋輸送機(jī)

- 污泥輸送機(jī)

- 刮板機(jī)(刮板輸送機(jī))

- 鏈斗輸送機(jī)

- 伸縮式皮帶輸送機(jī)

- 真空上料機(jī)

- 帶式輸送機(jī)

- 鱗板機(jī)

- 移動(dòng)式皮帶輸送機(jī)

- 大傾角輸送機(jī)

- 皮帶輸送機(jī)

- 螺旋輸送機(jī)

- 振動(dòng)輸送機(jī)

- 鏈板輸送機(jī)

- 滾筒輸送機(jī)

- 網(wǎng)帶輸送機(jī)

- 埋刮板輸送機(jī)

提升機(jī)械

- 雙斗提升機(jī)

- 翻斗提升機(jī)

- TD斗式提升機(jī)

- TH提升機(jī)

- NE型提升機(jī)

- TB垂直斗式提升機(jī)

- td160斗式提升機(jī)

- 垂直上料機(jī)

- 水泥提升機(jī)

- 螺旋垂直提升機(jī)

- 單斗提升機(jī)

- 畚斗提升機(jī)

- 撈坑脫水斗式提升機(jī)

- 挖斗提升機(jī)

- 斗式提升機(jī)(斗提機(jī))

- 板鏈斗式提升機(jī)

- 環(huán)鏈斗式提升機(jī)

- 皮帶斗式提升機(jī)

- 垂直提升機(jī)

- Z型提升機(jī)

- 垂直振動(dòng)提升機(jī)

- 物料提升機(jī)

給料機(jī)械

- 無(wú)塵投料站

- 鏈條式提升機(jī)

- 喂料機(jī)

- 自動(dòng)給料機(jī)

- 螺旋給料機(jī)

- 給礦機(jī)

- 雙螺旋給料機(jī)

- 圓盤(pán)式給料機(jī)

- 棒條振動(dòng)給料機(jī)

- 槽式給料機(jī)

- 擺式給料機(jī)

- 活化振動(dòng)給煤機(jī)

- 振動(dòng)放礦機(jī)

- 板式喂料機(jī)

- 甲帶給料機(jī)

- 電磁振動(dòng)給料機(jī)

- 電機(jī)振動(dòng)給料機(jī)

- 往復(fù)式給料機(jī)

- 圓盤(pán)給料機(jī)

- 螺旋給料機(jī)

- 板式給料機(jī)

- 振動(dòng)給料斗

- 葉輪給料機(jī)